Beautiful Work Tips About How Many Motors Can L298N Control

Arduino L298n Motor Control

Unlocking the Power of the L298N

1. Understanding the L298N Motor Driver

So, you're diving into the world of robotics or electronics and you've stumbled upon the L298N motor driver. Excellent choice! This unassuming chip is a workhorse for controlling DC motors and stepper motors. But the big question is: How many motors can this L298N actually control? Its a question that pops up more often than you'd think, and getting the answer right can save you from a lot of frustration (and maybe a few burnt components!).

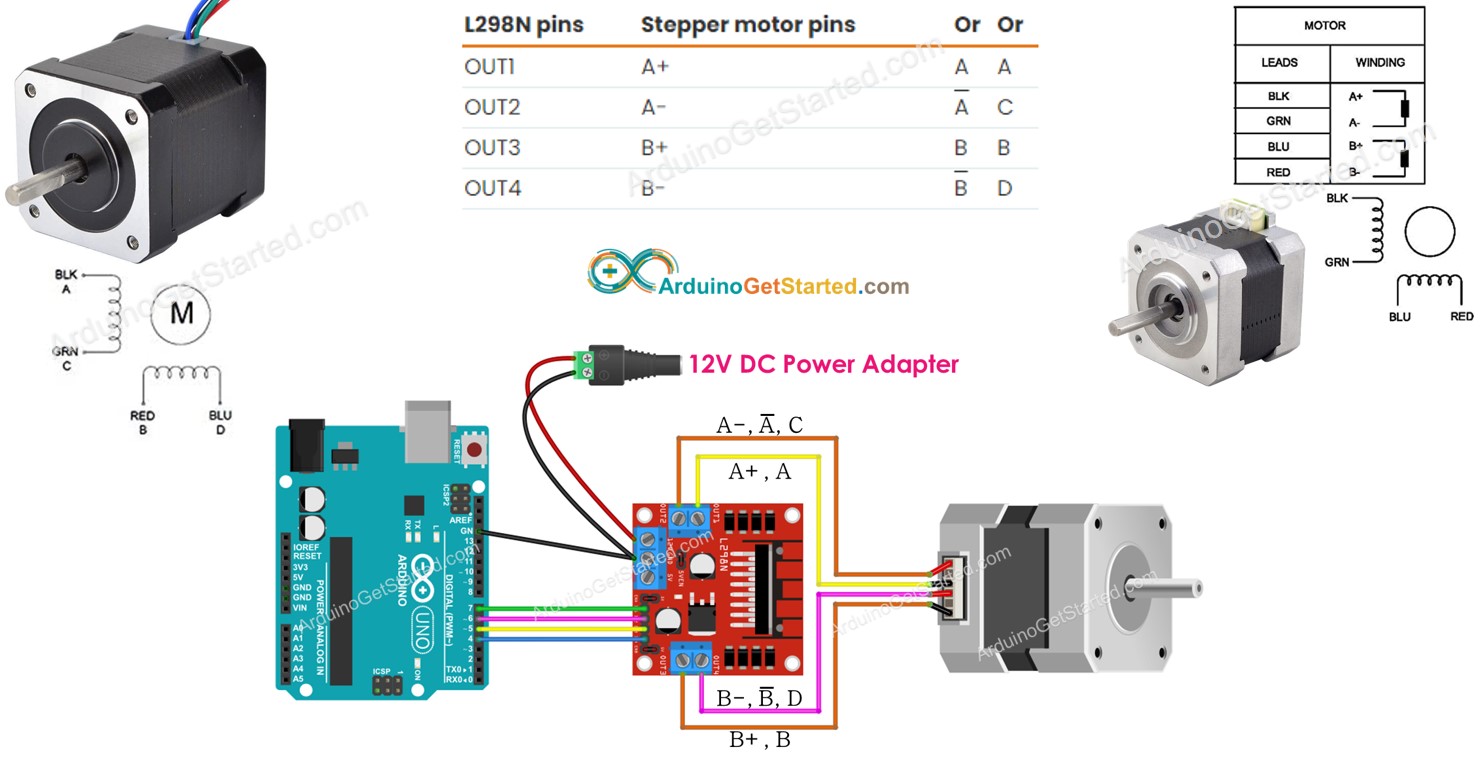

The L298N is essentially a dual H-bridge driver. Think of it as having two separate motor control circuits packed into one convenient package. Each H-bridge allows you to control the direction and speed of a single DC motor. This "dual" nature is key to understanding its motor-driving capabilities.

This means the L298N can control two separate DC motors independently. You can make one motor spin forward while the other spins backward, or control their speeds independently, all thanks to its clever design. This makes it perfect for applications like robotics projects, where you might need to control the left and right wheels of a robot.

However, its important to remember that while it can control two motors, the amount of current each motor draws matters a great deal. We'll get into the details of current limitations shortly. It's like inviting friends over for pizza; you can technically invite a dozen people, but if you only have one pizza, some people are going to be disappointed (and possibly hungry!).

2. The Nitty-Gritty

Here's where things get a little more technical, but stick with me! The L298N has a specified maximum current rating. You'll typically see it listed around 2A per channel (or sometimes 4A total, but that's typically pushing its limits). That "2A per channel" part is crucial. It means each of those two H-bridges we talked about can, in theory, handle up to 2 amps of current.

However, and this is a big however, that 2A rating is more of an absolute maximum and less of a comfortable operating range. In the real world, pushing the L298N to its absolute limit is a recipe for overheating and potentially damaging the chip. It's like running a marathon at full sprint — you might make it a little ways, but you'll probably crash and burn pretty quickly.

To keep your L298N happy and functioning reliably, it's generally recommended to stay well below that 2A limit. A good rule of thumb is to aim for around 1A or less per channel, especially if you're running the motors continuously. This gives the chip some breathing room and helps prevent overheating. Heat sinks are your friends here. Slap one of those on the L298N, and it will be much happier handling higher currents.

Before connecting any motors to your L298N, always check the motor's datasheet to see how much current it draws under typical operating conditions, and especially under stall conditions (when the motor is trying to move but is blocked). Stall current can be significantly higher than the normal running current, and exceeding the L298N's limit can quickly lead to problems. It's like knowing the weight limit of an elevator before you pack it with all your furniture — a little preparation can prevent a disaster!

Going Beyond Two

3. Exploring Alternatives and Expansion

Technically, no. An individual L298N chip is designed to control a maximum of two DC motors or one stepper motor. But, that doesn't mean you're limited to just two motors for your entire project. There are ways to expand your motor control capabilities.

The most straightforward method is to simply use multiple L298N chips. If you need to control four DC motors, you can use two L298N chips. Just make sure your microcontroller has enough pins to control all of them! Think of it as building a bigger house when you need more rooms — you just add more modules.

Another option is to explore other motor driver chips. There are many other options available, some of which are specifically designed to handle higher currents or control more motors with a single chip. For example, the TB6612FNG is a popular alternative that offers similar functionality to the L298N but with better efficiency and a slightly higher current rating.

For more complex projects with many motors, you might even consider using a dedicated motor controller board. These boards often include multiple motor drivers, built-in current protection, and convenient interfaces for connecting to your microcontroller. These are kind of like pre-fabricated homes designed for specific purposes — they make complex jobs easier.

4. Practical Considerations

Power supply is a crucial aspect. The L298N requires a suitable power supply to function correctly. Make sure your power supply can provide enough voltage and current to meet the demands of your motors. Underpowering your motors can lead to erratic behavior or even damage to the motors and the L298N.

Heat management is also critical. As we mentioned earlier, the L298N can generate significant heat, especially when driving motors at higher currents. Using a heat sink is highly recommended, and you might even consider using a small fan to provide additional cooling. Overheating can significantly reduce the lifespan of the chip and even cause it to fail prematurely. It's like making sure your car has enough coolant — overheating is bad news!

Choosing the right voltage is as important as choosing the right current. The L298N can typically handle motor voltages up to 35V. Check the voltage requirements of your motors and make sure they are compatible with the L298N. Using too high of a voltage can damage your motors, while using too low of a voltage can result in poor performance.

Finally, don't forget about proper wiring. Ensure all your connections are secure and that you are using the correct gauge of wire for the current you are drawing. Loose connections can cause voltage drops and erratic motor behavior, while undersized wires can overheat and create a fire hazard. Think of it as making sure all the pipes in your house are properly connected to avoid leaks and flooding!

In Summary

5. Recap and Best Practices

So, to recap: the L298N can directly control two DC motors (or one stepper motor), but the real limitation is the current draw of those motors. Stay below 1A per channel for reliable operation, use heat sinks, and always check your motor's datasheet to avoid overloading the chip.

Remember, the L298N is a great starting point for basic motor control, but there are many other motor driver options available that may be better suited for more demanding applications. Don't be afraid to explore and experiment to find the best solution for your project.

By carefully considering the current requirements, heat management, and power supply, you can effectively use the L298N to bring your robotic creations to life. And who knows, maybe you'll even build the next Roomba!

And finally, if you are going to use multiple L298N's for one project, make sure that each has its own power source, this will ensure that they all function optimally and avoid underpowering any of them. A good practice is to have the same power source and split that to different L298N's if they will need the same voltage.