Neat Tips About Can 3 Phase Have Wires

Understanding Three-Phase Power

1. The Basic Premise of Three-Phase Systems

So, you're diving into the world of electrical systems, specifically three-phase power, and you've got a question: "Can 3 phase have 3 wires?" It's a good one! At its core, three-phase power is a method of distributing electricity that uses three alternating currents, each out of phase with the others. Think of it as three rivers of electricity flowing together, working in harmony. This approach provides a smoother, more efficient power delivery compared to single-phase systems, which are what you typically find in homes.

Now, why is this smoother and more efficient? Well, imagine pushing a heavy box. Would you rather have one person pushing intermittently, or three people pushing in a coordinated, constant manner? Three-phase power is like the latter. This makes it ideal for industrial applications where heavy machinery and large loads are the norm. It's the workhorse of factories, hospitals, and data centers, powering the world around us.

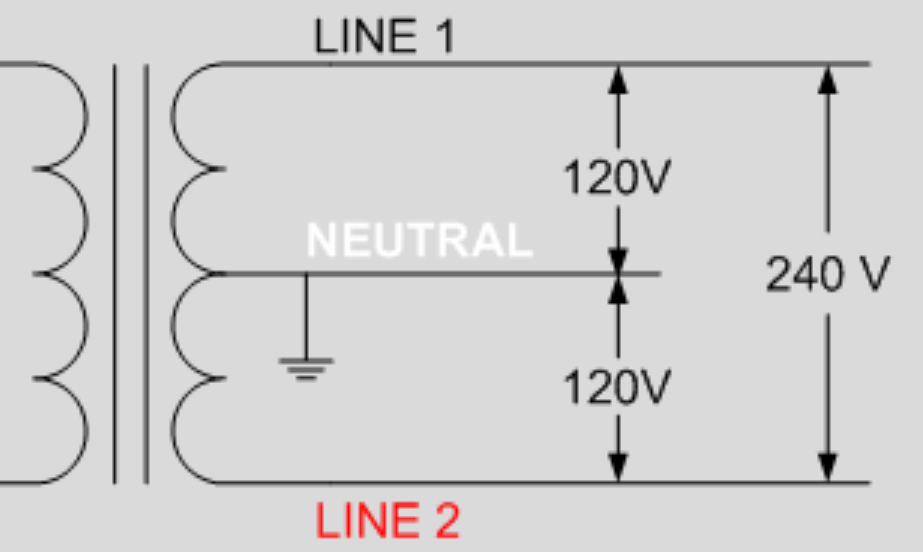

The standard configuration involves three 'hot' wires, each carrying a different phase of the alternating current. These phases are typically spaced 120 degrees apart, ensuring a constant power supply. However, it's the interaction of these phases, the clever engineering behind the scenes, that truly unlocks the benefits of three-phase power. This coordination allows for smaller conductors and more efficient motor operation, leading to significant cost savings and improved performance.

But before we get ahead of ourselves, let's tackle the initial question about the number of wires. The answer isn't always a straight 'yes' or 'no,' and understanding why requires a deeper dive into the different types of three-phase systems.

Single Phase 3wire Diagram 3 Plug Wiring

Three Wires vs. Four Wires

2. Delta and Wye Configurations Explained

Okay, here's where things get a bit more technical, but stick with me! The number of wires in a three-phase system often depends on the configuration: specifically, whether it's a delta or a wye (sometimes written as "Y") configuration. These are the two common ways to arrange the three phases, each with its own set of pros and cons.

A delta configuration, as the name suggests, looks like the Greek letter delta (). It consists of three wires connected in a closed loop. In its simplest form, yes, a delta system can operate with just three wires. There's no neutral wire in this setup, which can be a cost-effective solution for certain applications. However, a key drawback of a standard delta system is that it doesn't readily provide a neutral point for single-phase loads. Think of it as three power sources perfectly balanced, but without a common ground.

On the other hand, a wye configuration looks like the letter Y. The three phases are connected to a common neutral point, which is then grounded. This gives you four wires: three phase wires and a neutral wire. The presence of the neutral wire is a game-changer. It allows you to derive single-phase power from the three-phase system, which is crucial for powering smaller loads like lighting and office equipment within a larger industrial facility. This is why you'll often see a four-wire wye system in buildings with a mix of heavy machinery and standard outlets.

So, can 3 phase have 3 wires? Absolutely, in a delta configuration. But in a wye configuration, you'll typically find four wires, including that vital neutral. The choice between the two depends heavily on the specific needs of the application and the types of loads being powered.

Grounded vs. Ungrounded Systems

3. Why Grounding Matters in Electrical Systems

Beyond just the number of wires, it's also crucial to consider whether a three-phase system is grounded or ungrounded. Grounding plays a vital role in safety, helping to prevent electrical shock and equipment damage. It provides a low-resistance path for fault currents to flow, allowing protective devices like circuit breakers to trip and isolate the problem.

In a grounded system, the neutral point (in a wye configuration) or a derived neutral point (in a delta configuration) is connected to the earth. This creates a reference point for the voltage and limits the potential for voltage fluctuations. A grounded system is generally considered safer, as it reduces the risk of overvoltages and provides a clear path for fault currents. This is especially important in environments where people may come into contact with electrical equipment.

An ungrounded system, as the name implies, has no direct connection to earth. While it might seem counterintuitive, there are situations where an ungrounded system can be advantageous. For example, in certain industrial applications where a single ground fault wouldn't necessarily require immediate shutdown. This is because the system can continue to operate with a single fault to ground, allowing for a more controlled shutdown or repair process. However, this comes at the cost of increased risk in the event of a second ground fault, which can cause a short circuit and potentially damage equipment.

Choosing between a grounded and ungrounded system is a complex decision that depends on a variety of factors, including the application, the equipment being powered, and the overall safety requirements. Grounding methods, including impedance grounding, can also be used to limit fault currents.

Phase Distribution Board Wiring Diagram and Connection Procedure.png)

Applications and Considerations

4. When a 3-Wire System Makes Sense

So, where would you actually use a three-wire three-phase system in the real world? Typically, you'll find them in situations where you primarily need to power large, balanced three-phase loads, and you don't need to supply single-phase power from the same system. Think of large industrial motors, specialized heating equipment, or even some types of welding machines. These applications thrive on the balanced, efficient power delivery of a three-phase delta system.

One advantage of a three-wire delta system is that it can be more cost-effective to install, as it requires one less conductor. This can be significant in large installations where the cost of wiring can add up quickly. However, this cost saving comes at the expense of flexibility. Without a neutral wire, you can't easily tap into the system to provide single-phase power for smaller loads, which can be a limitation in some environments.

Another consideration is voltage imbalance. In a three-wire system, voltage imbalances can be more pronounced than in a four-wire system with a neutral. This is because the neutral wire in a four-wire system helps to equalize the voltage across the phases. Voltage imbalances can lead to increased motor heating, reduced equipment lifespan, and overall inefficiency. Therefore, careful load balancing is crucial in three-wire systems.

Ultimately, the decision to use a three-wire or four-wire three-phase system depends on a careful evaluation of the specific application requirements. It's a balancing act between cost, efficiency, flexibility, and safety. Consulting with a qualified electrical engineer is always recommended to ensure that the chosen system is appropriate for the intended use.

3 Phase SPD Connection Diagram

Safety First

5. Important Precautions and Best Practices

Regardless of whether you're dealing with a three-wire or four-wire three-phase system, safety should always be the top priority. Three-phase power can deliver a significant amount of energy, and working with it improperly can lead to serious injury or even death. It's absolutely essential to follow all applicable electrical codes and regulations and to use appropriate personal protective equipment (PPE).

Before working on any electrical equipment, always de-energize the circuit and verify that it is indeed dead using a reliable voltage tester. Never assume that a circuit is de-energized just because the breaker is switched off. Lockout/tagout procedures should be strictly followed to prevent accidental re-energization of the circuit while work is in progress. These procedures involve physically locking the disconnect switch in the off position and attaching a tag indicating that the circuit is being worked on.

When working with three-phase power, it's also important to be aware of the potential for phase-to-phase and phase-to-ground faults. These types of faults can result in high fault currents and arc flash hazards. Arc flash is a dangerous phenomenon that occurs when a short circuit creates an explosive release of energy, potentially causing severe burns and other injuries. Proper arc flash PPE, including flame-resistant clothing, face shields, and gloves, should be worn when working on or near energized equipment.

Finally, regular maintenance and inspection of three-phase systems are crucial for ensuring safe and reliable operation. This includes checking for loose connections, damaged insulation, and other signs of wear and tear. Any issues should be addressed promptly by a qualified electrician. Remember, working with electricity is not a DIY project. Always leave it to the professionals.