Stunning Tips About Is It Safe To Splice Wires With Electrical Tape

Splices In Electrical Wiring How To Splice Circui

Is Electrical Tape Your Go-To Wire Splicing Solution? Let's Get Real

1. The Allure of Electrical Tape

Okay, let's be honest. We've all been there. You're fiddling with some wires, maybe installing a new light fixture, or fixing a dodgy connection, and electrical tape is staring you right in the face. It's tempting, right? Just a quick wrap and you're done. But hold on a second — is it really the best way? Is it even safe? That's what we're diving into today. Electrical tape has its place, sure, but wire splicing? That's a whole other ballgame.

Think of it like this: Electrical tape is like that band-aid you slap on a wound you probably should have gotten stitches for. It covers it up, makes it look better temporarily, but the underlying issue is still there, potentially festering. With wires, that "festering" can mean loose connections, overheating, and even fires. Not exactly the outcome you were hoping for, I'd wager.

The problem with relying solely on electrical tape for splicing is its tendency to loosen over time. Temperature fluctuations, vibration, and even just the adhesive drying out can cause it to unravel. And when it unravels, those wires are exposed, creating a potential hazard for shorts, shocks, and, you guessed it, fire. So, while it might seem like the easy fix in the moment, it's often a recipe for trouble down the road. Think of future you and the potential headaches and hazards you could be avoiding!

So, what are the alternatives? We'll get to that, but first, let's just acknowledge that the quick-fix appeal of electrical tape is strong. But a little extra effort and the right materials can make a world of difference in terms of safety and longevity. It's about doing the job right, not just doing it fast, wouldn't you agree?

The Dangers Lurking Behind a Taped Connection

2. Why Electrical Tape Alone Isn't Always Your Friend

Let's dig a little deeper into why relying solely on electrical tape for wire splicing can be a risky proposition. It's not just about the tape potentially unraveling, although that's a significant concern. It's also about the very nature of the connection itself. A properly spliced wire creates a secure, low-resistance path for electricity to flow. A poorly spliced, tape-reliant connection? Not so much.

When wires are simply twisted together and taped, there's a greater chance of a loose connection. This looseness creates resistance, and resistance generates heat. Over time, this heat can melt the tape, further loosening the connection and exacerbating the problem. It's a vicious cycle, and it can lead to some pretty nasty consequences. Think melted insulation, charred wires, and the smell of burning plastic — not exactly what you want your home smelling like.

Another often-overlooked factor is corrosion. If the wires aren't properly protected from moisture, they can corrode over time. This corrosion further increases resistance and weakens the connection. Electrical tape can offer some minimal protection, but it's far from a foolproof barrier against moisture. The best analogy? Imagine you are trying to protect a metal object from water by just wrapping it in a paper. It might prevent minor splashes, but it won't protect it from being submerged. Proper wire connectors and enclosures offer far superior protection.

Ultimately, using electrical tape as the sole splicing method is like using a flimsy lock on a valuable safe. It might deter the casual glance, but it's not going to hold up against a determined effort (or, in this case, the relentless forces of heat, moisture, and vibration). It's better to invest in proper splicing techniques and materials to ensure a safe and reliable connection.

Safe Splicing Alternatives

3. Embrace the Power of Proper Connections

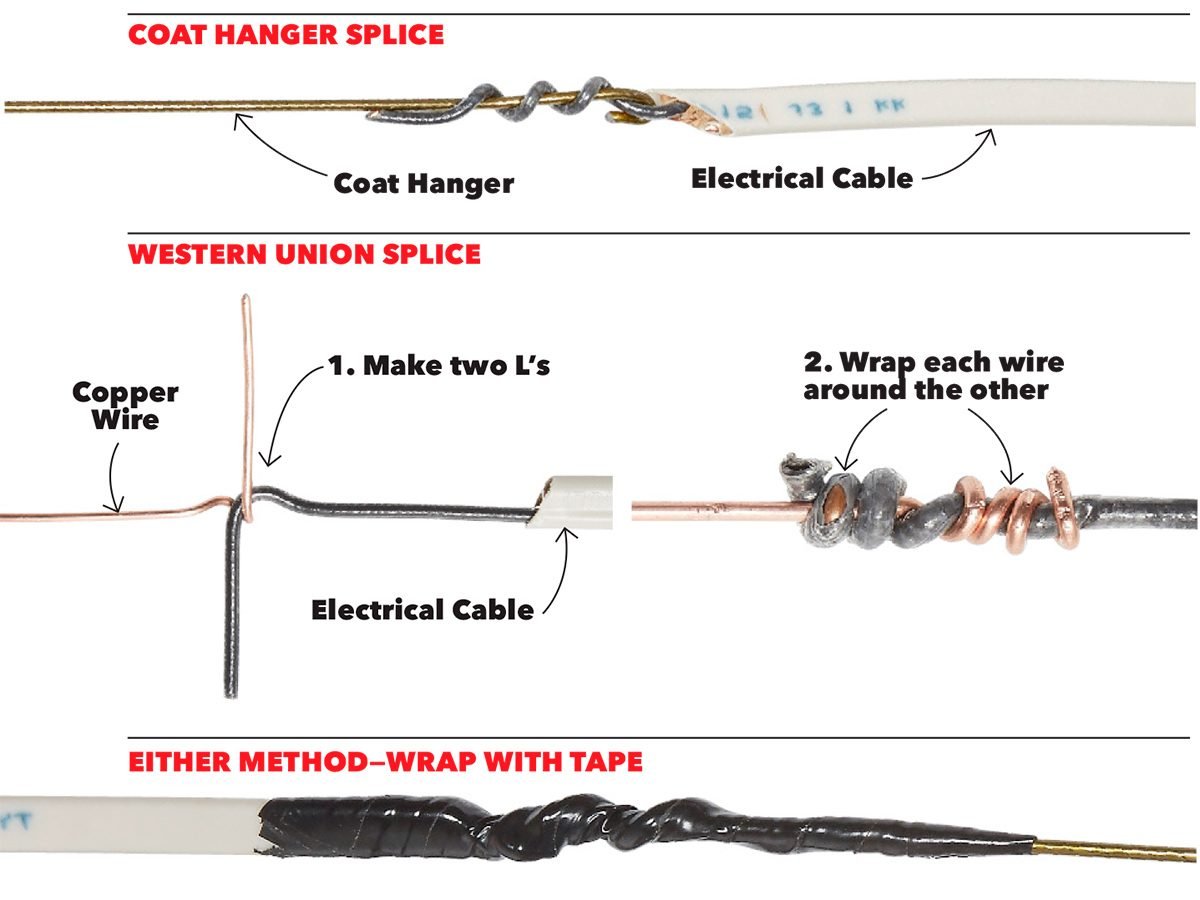

Okay, so we've established that electrical tape alone isn't the splicing superhero we might have once thought it was. So, what are the alternatives? Thankfully, there are several much safer and more reliable methods for joining wires. These options provide secure connections, minimize resistance, and offer better protection against the elements.

Wire connectors, often called "wire nuts," are probably the most common and widely accepted alternative. These small, plastic caps screw onto the twisted ends of wires, creating a tight and secure connection. They're easy to use, relatively inexpensive, and available in a variety of sizes to accommodate different wire gauges and numbers of wires. Just strip the ends of the wires, twist them together (preferably with pliers designed for the job), and screw on the wire connector. It's like a tiny, wire-holding fortress!

Another great option is push-in connectors. These connectors are even easier to use than wire nuts. Simply strip the wires and push them into the designated slots. The internal spring-loaded mechanism creates a firm and reliable connection. Push-in connectors are especially useful in tight spaces where it might be difficult to twist wires together. They're a little pricier than wire nuts, but the ease of use can be worth the extra cost, especially if you're working on a complicated wiring project.

For more demanding applications, such as outdoor wiring or connections exposed to moisture, consider using crimp connectors with heat shrink tubing. Crimp connectors are metal sleeves that are crimped onto the wires using a specialized crimping tool. The heat shrink tubing is then slid over the connection and heated with a heat gun, creating a waterproof and airtight seal. This method provides a very strong and durable connection that can withstand harsh conditions. It might take a little more effort and equipment, but the peace of mind is well worth it.

How To Use Electrical Tape Angi

Electrical Tape Still Has a Role (But Not as a Primary Splicer)

4. When Electrical Tape Earns Its Keep

Now, before you toss all your electrical tape in the trash, let's be clear: it still has a role to play in electrical work. It's just not the star of the show when it comes to splicing wires. Think of it as a supporting actor, not the leading man.

The primary use for electrical tape is to insulate and protect existing connections that have already been properly made with wire connectors or other approved methods. Wrapping a wire nut with electrical tape, for example, can provide an extra layer of protection against moisture and accidental contact. It's like adding a little extra security to your fortress, just in case.

Electrical tape is also useful for marking wires, bundling wires together, or temporarily holding wires in place while you're working on a project. It can even be used to repair minor damage to wire insulation, but only as a temporary fix until the wire can be properly replaced or repaired. Think of it as a quick bandage for a minor scratch, not a solution for a deep wound.

Ultimately, electrical tape is a valuable tool in any electrician's arsenal, but it should always be used in conjunction with proper splicing techniques and materials. Don't rely on it as a substitute for a secure and reliable connection. It's a good finishing touch, but not a foundation.

Don't Be "That Guy"

5. Keeping it Legal and Safe

Beyond the technical aspects of wire splicing, it's crucial to consider local electrical codes and regulations. These codes are in place to ensure the safety of your home and everyone in it. Ignoring them can lead to serious consequences, including fines, insurance claim denials, and, most importantly, increased risk of electrical hazards.

Most electrical codes prohibit the use of electrical tape as the sole means of splicing wires. They require the use of approved connectors, such as wire nuts, push-in connectors, or crimp connectors. It's always a good idea to consult your local electrical code or a qualified electrician to ensure that your wiring practices are compliant.

Another important aspect of safe wiring practices is working with de-energized circuits. Always turn off the power at the breaker before working on any electrical wiring. Double-check that the power is off by using a non-contact voltage tester. It's better to be safe than sorry, and a little extra precaution can prevent serious injury or even death.

Finally, if you're not comfortable working with electrical wiring, don't hesitate to call a qualified electrician. Electricity is not something to be taken lightly, and a professional electrician has the knowledge, skills, and experience to handle even the most complex wiring projects safely and effectively. It's an investment in your safety and peace of mind.